That dreaded click instead of an engine roar—your car battery has died at the worst possible moment. With your NAPA jump starter sitting in your trunk, you have a solution at hand, but only if you know exactly how to use it correctly. This guide delivers the precise steps to safely jump-start your vehicle using your NAPA unit, avoiding common mistakes that could damage your car’s electrical system or create dangerous situations.

Most drivers own a jump starter but have never practiced using it until they’re stranded. Your NAPA jump starter can revive dead batteries in under two minutes when used properly, but incorrect connection sequences cause thousands of preventable accidents annually. By the end of this guide, you’ll confidently connect your NAPA unit in any emergency situation, understand its advanced features, and maintain it for years of reliable service.

Positioning Your NAPA Jump Starter for Maximum Safety

Place your NAPA jump starter on stable, dry ground near your vehicle’s battery—never on the engine itself where moving parts could cause damage. The unit should sit within easy reach of both battery terminals without stretching cables. For optimal safety, position the jump starter at least 18 inches away from the battery to minimize exposure to potential hydrogen gas emissions.

Ensure your vehicle is in park or neutral with the parking brake firmly engaged before connecting any cables. Turn off all electrical loads—headlights, radio, climate control, and phone chargers—as these create parasitic drains that reduce available starting power. If using another vehicle as a power source (not recommended with NAPA’s standalone units), position both vehicles so batteries face each other without physical contact.

Identify Terminal Polarity Before Connecting

Your battery has clearly marked positive (+) and negative (-) terminals, typically color-coded red and black respectively. NAPA jump starters use matching color-coded clamps that must connect to corresponding terminals. Examine your battery closely—some European models mount terminals on the side rather than the top, and corrosion can obscure markings.

If terminal symbols aren’t visible due to corrosion, look for tiny + and – engravings on the battery case edges. Never guess polarity—reversed connections trigger NAPA’s safety systems but can still damage sensitive vehicle electronics. Clean heavily corroded terminals with a wire brush before attempting connections, as poor contact reduces power transfer and creates dangerous heat.

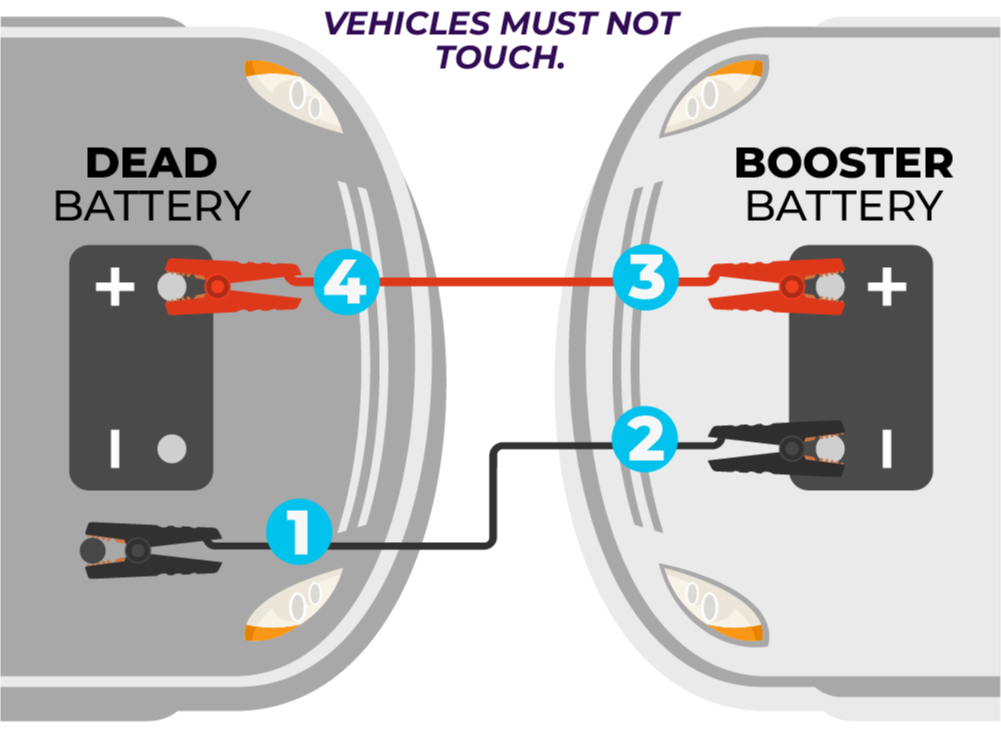

Connection Sequence That Prevents Dangerous Sparks

Connect your NAPA jump starter cables in this exact order to eliminate spark risks near explosive battery gases: First attach the red positive clamp to your dead battery’s positive terminal. Ensure solid metal-to-metal contact by wiggling the clamp until it seats firmly—loose connections cause arcing that damages terminals.

Next, connect the black negative clamp to the vehicle’s engine block or chassis, not the battery’s negative terminal. Choose an unpainted metal surface at least 12 inches from the battery, like a bolt on the engine head. This “grounding” technique prevents sparks near the battery where hydrogen gas may accumulate.

Verify Secure Connections Before Powering On

Before activating your NAPA unit, tug gently on each clamp to confirm solid attachment. The red clamp should resist moderate pulling force without sliding. Check that both clamps contact bare metal—paint, grease, or corrosion creates resistance that reduces available starting power.

Ensure the positive and negative clamps never touch each other or nearby metal surfaces. Even momentary contact while connecting creates dangerous arcs that can melt cable insulation. NAPA’s heavy-gauge cables resist damage but aren’t immune to short circuits caused by careless handling.

Activate Your NAPA Unit Correctly

Flip the main power switch on your NAPA jump starter—some models require holding the button for 2-3 seconds. Watch for indicator lights confirming proper operation: solid green typically means ready, while flashing red indicates low charge. If your NAPA unit displays a reverse polarity warning, disconnect immediately and recheck terminal identification.

Never activate the jump starter before connections are secure. Modern NAPA units have built-in protection, but older models could deliver uncontrolled current surges that damage vehicle electronics. Wait 10-15 seconds after connections before powering on to allow internal capacitors to stabilize.

Starting Your Vehicle Without Damaging Electrical Systems

Enter your vehicle and attempt to start the engine immediately after connecting your NAPA jump starter—don’t wait. Turn the key or press the start button for no more than 5 seconds at a time. Extended cranking drains your jump starter unnecessarily and overheats starter motors.

If the engine doesn’t start, wait 30 seconds between attempts to prevent NAPA’s internal circuits from overheating. Three failed attempts indicate either insufficient jump starter charge, poor cable connections, or a more serious vehicle problem. During cold weather (below freezing), allow 10 seconds between attempts as thickened oil increases engine resistance.

Proper Procedure After Successful Start

Once your engine fires, let it idle for 2-3 minutes before disconnecting cables. This allows your vehicle’s alternator to begin recharging its own battery. Keep all electrical accessories off during this period—no headlights, radio, or climate control that could stall the engine.

Check your dashboard for warning lights that might indicate charging system problems. A persistent battery light suggests your alternator isn’t maintaining charge, meaning you’ll need professional service even after jump-starting. Don’t drive far with this light illuminated—you might strand yourself again.

Safe Disconnection Process to Prevent Damage

Remove NAPA cables in reverse order of connection: black negative clamp first, then red positive clamp. This sequence prevents sparks near the battery that could ignite hydrogen gas. When removing the negative clamp, angle it away from the vehicle to avoid accidental contact with metal surfaces.

Coil cables loosely after use—never wrap tightly around the jump starter as this stresses internal wire connections. Store clamps in designated holders to prevent metal contact during storage. Modern NAPA units automatically power down after disconnection, but verify all indicators have turned off before storing.

Troubleshooting Common NAPA Jump Starter Issues

No Power Response From Unit

If your NAPA jump starter shows no lights when powering on, verify the main switch is fully engaged—some models have stiff toggles that require firm pressure. Check USB charging ports for lint or debris preventing full connection. Try a different charging cable as micro-USB ports wear out over time with frequent use.

When completely unresponsive, the internal lithium-ion battery may have entered deep discharge protection. Connect to a wall charger for 15-20 minutes before attempting power-on—most NAPA units recover from this state with brief charging. If still unresponsive after extended charging, contact NAPA for battery replacement.

Weak Starting Power Despite Full Charge

Dim interior lights or slow cranking indicate insufficient power delivery. Recharge your NAPA jump starter using the included wall adapter for 4-6 hours—partial charges reduce available capacity. In cold weather (below 40°F), warm the unit in your jacket pocket for 10 minutes before use, as lithium-ion batteries lose 20-30% capacity in freezing temperatures.

For diesel engines or large trucks, ensure you’re using NAPA’s heavy-duty model rated for high-compression starts. Standard units may not provide sufficient cranking amps—check your vehicle’s CCA (cold cranking amps) requirement against your jump starter’s specifications.

Reverse Polarity Warning Activation

NAPA’s safety systems prevent operation when polarity is reversed. Disconnect immediately and recheck terminal identification—positive terminals are often slightly larger than negative ones. Clean terminals thoroughly with a wire brush to reveal obscured + and – markings.

If warnings persist after correct connection, inspect cables for damaged insulation allowing internal wires to cross-contact. Replace the cable assembly if you notice exposed copper or melted sections near the clamps. Never bypass polarity warnings—this risks catastrophic damage to your vehicle’s computer systems.

Maintaining Your NAPA Jump Starter for Years of Reliability

Recharge your NAPA jump starter every 3 months regardless of use. Lithium-ion batteries self-discharge over time, and deep discharge significantly shortens lifespan. Store at 40-60% charge in moderate temperatures—avoid leaving in vehicles during extreme heat or cold, which degrades battery performance.

Cable and Clamp Maintenance Routine

Monthly, apply dielectric grease to clamp teeth to prevent corrosion—this maintains optimal electrical contact. Store cables loosely coiled in the provided case—tight wrapping creates stress points that lead to internal wire breaks. Inspect clamps for metal fatigue, especially around pivot points where repeated use causes microscopic cracks.

Replace the entire cable assembly if you notice frayed insulation, bent clamp jaws, or weak spring tension. NAPA offers replacement cables for most models—don’t risk using damaged components that create dangerous resistance points.

Battery Health Monitoring Protocol

Use your NAPA jump starter’s built-in battery tester monthly by connecting clamps to a known good 12V source. This cycles internal circuits and verifies all systems operate correctly. LED indicators should show full charge capacity—dim or inconsistent lights indicate declining battery health requiring replacement.

For units with digital displays, note the voltage reading when fully charged—it should be 12.6-12.8V. Readings below 12.4V indicate aging batteries that may fail when needed most. NAPA lithium units typically last 3-5 years with proper maintenance before requiring battery replacement.

Advanced Features That Enhance Emergency Situations

Your NAPA jump starter’s USB ports can charge phones and tablets during emergencies, but use sparingly—this drains the main battery quickly. Prioritize jump-starting your vehicle before using secondary features. Most units provide enough power for 2-3 full phone charges when fully powered.

The built-in LED flashlight delivers 100+ lumens of light with multiple modes—steady, strobe, and SOS. This proves invaluable during nighttime breakdowns, providing 48+ hours of continuous light on full charge. Activate the strobe mode when working near traffic for increased visibility.

Cold Weather Performance Optimization

Below 32°F, NAPA battery capacity drops significantly. Keep the unit inside your vehicle cabin rather than the trunk during winter months. When needed, warm the jump starter in your hands for 2-3 minutes before use—this improves chemical reaction rates inside the battery.

For extreme cold (below 0°F), consider NAPA’s AGM battery models which maintain performance better than standard lithium units in freezing temperatures. These heavy-duty models deliver consistent cranking power when standard units might fail.

Mastering your NAPA jump starter takes practice, but following these precise steps ensures safe, effective battery boosting every time. Test your unit quarterly by connecting to your vehicle battery without starting—this verifies operational readiness without draining the unit. With proper care, your NAPA jump starter provides years of reliable emergency power, turning dead battery situations into minor inconveniences rather than major headaches.